Enhance Your Service Operations With Reliable Industrial Scales

In today's competitive landscape, the accuracy of industrial ranges plays a pivotal function in improving general company operations. Exact weighing not just mitigates costly disparities throughout various sectors, such as manufacturing and logistics, but also makes certain compliance with stringent market requirements. As companies look for to maximize effectiveness, recognizing the various sorts of ranges and their technical innovations becomes crucial. However, the choice procedure can be complex, and the effects of these choices can substantially impact operational success. What aspects should be considered to guarantee the right devices is picked for your details needs?

Importance of Accurate Evaluating

Accurate evaluating is critical in numerous commercial applications, as even minor disparities can cause significant economic losses and functional ineffectiveness. Industries such as manufacturing, logistics, and food processing depend on specific measurements to ensure item top quality, regulatory conformity, and optimal resource management. Unreliable weights can cause overproduction, waste of raw materials, or inadequate supply, affecting success and client complete satisfaction.

Additionally, precise considering is important for security and environmental compliance. In the chemical market, incorrect dimensions can lead to inappropriate mixtures, resulting in dangerous scenarios or legal ramifications. In the food industry, accurate evaluating is important for sticking to nutritional labeling requirements, guaranteeing that customers get precise details pertaining to the products they buy.

The integration of trustworthy commercial scales not just enhances functional efficiency yet likewise sustains data-driven decision-making. Investing in top notch commercial weighing solutions is necessary for companies intending to maintain an affordable edge in today's dynamic industry.

Sorts Of Industrial Scales

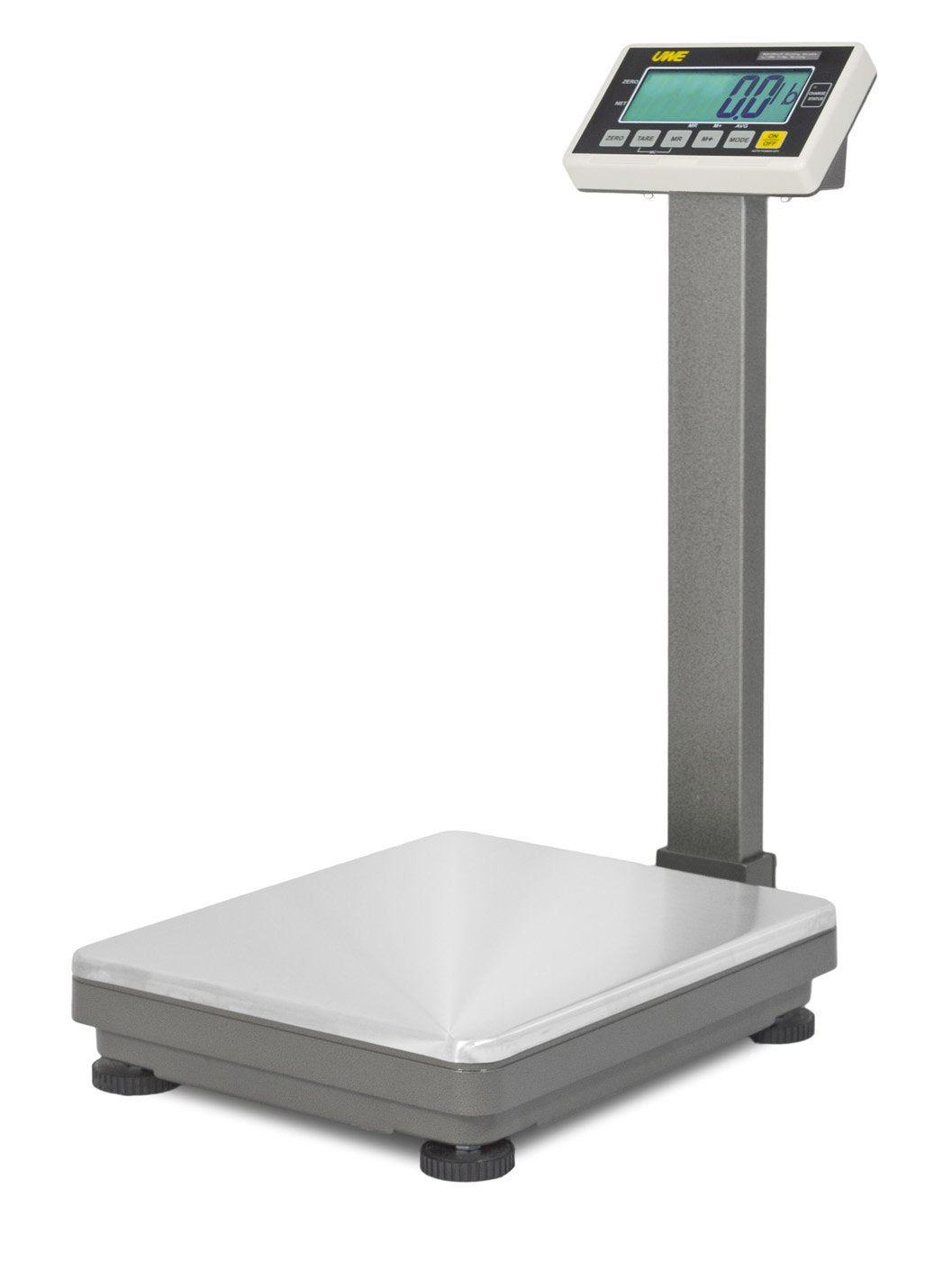

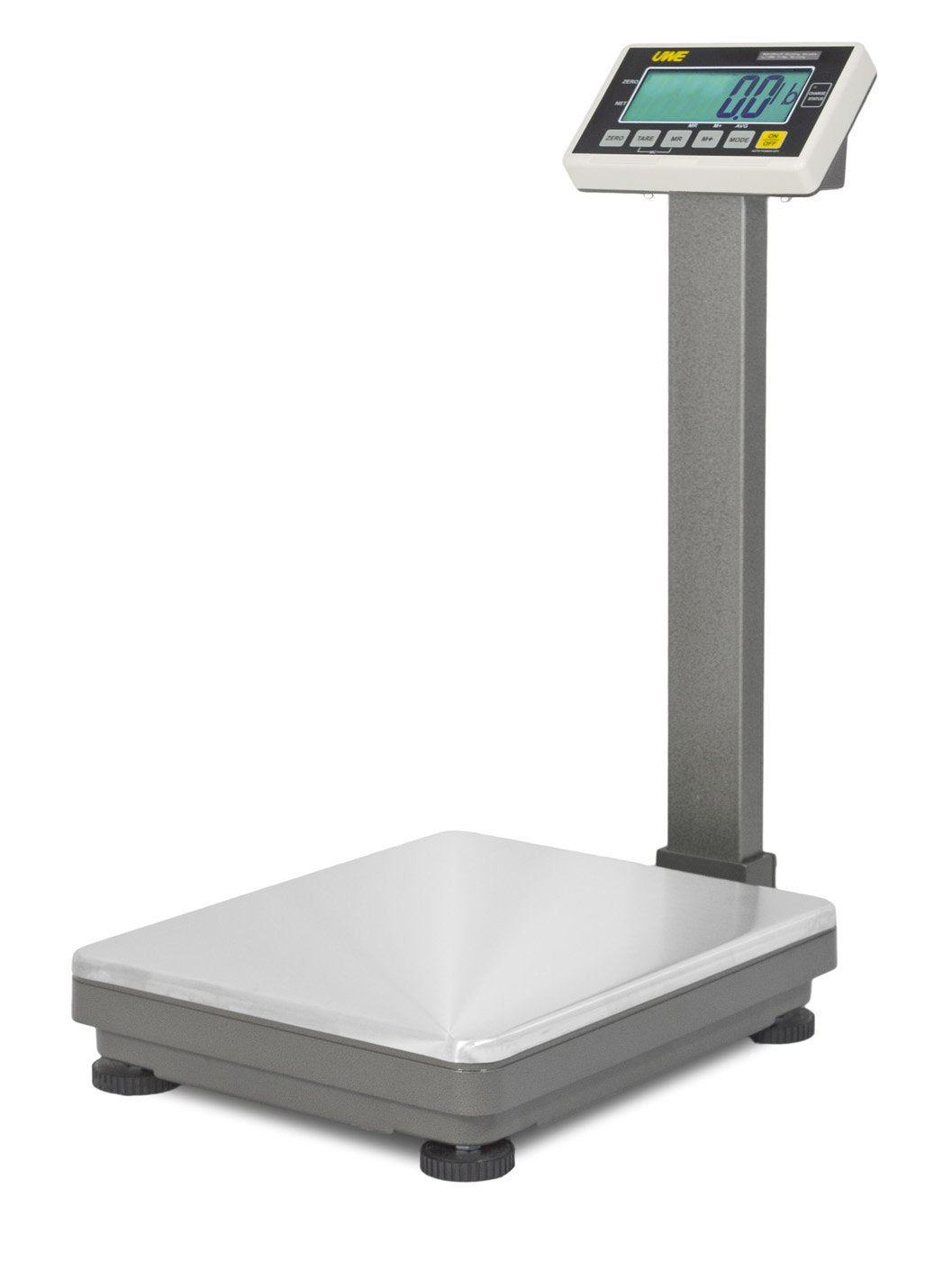

Industrial scales come in different types, each developed to fulfill certain considering requirements throughout various markets. Amongst the most usual kinds are system scales, which offer a large evaluating surface suitable for heavy items, making them excellent for warehouses and making facilities. These ranges frequently include digital screens for simple reading.

An additional type is bench ranges, which are typically smaller sized and portable, perfect for usage in research laboratories or retail environments. They enable for fast measurement of smaller items while keeping accuracy. For applications calling for the weighing of liquids, container scales are especially developed to measure the weight of storage space containers, making certain accurate supply monitoring.

Additionally, flooring scales are used for evaluating hefty loads on the ground level, often used in delivery and obtaining divisions. Crane scales are likewise significant; they are suspended from a framework to evaluate hefty materials in commercial setups. Lastly, lots cells play a critical role in many scales, transforming push into an electric signal for precise weight measurement. Each type of industrial scale offers a special objective, improving operational performance across varied sectors.

Advantages of Modern Innovation

Furthermore, modern-day commercial scales frequently come equipped with connection attributes that make it possible for smooth integration with other systems, such as stock monitoring and production tracking. This interconnectivity fosters an extra cohesive workflow and decreases downtime, as organizations can keep track of efficiency metrics and make data-driven decisions promptly.

Furthermore, many modern scales use adjustable setups and user-friendly interfaces, enabling drivers to adjust their devices for certain functional demands. Boosted resilience and strength versus extreme ecological problems better add to the durability and reliability of modern-day ranges, guaranteeing they can endure the rigors of commercial usage.

Choosing the Right Tools

Various industries may need distinctive types of scales, such as flooring scales for hefty lots, bench scales for smaller things, or portable scales for adaptability. Additionally, considering the setting in which the scales will be used is essential. Tools used in harsh environments might require to be sturdy and immune to dirt, wetness, or extreme temperature levels.

One more critical factor is the innovation utilized in the ranges. Digital ranges typically supply boosted precision and simplicity of use, while analog scales might be enough for much less demanding applications. It is essential to evaluate the scalability of the click to read equipment, ensuring that it can accommodate future growth or changes in manufacturing processes.

Finally, services should take into consideration the reputation and integrity of makers, as buying high-quality equipment can lead to long-lasting cost financial savings and improved functional efficiency.

Upkeep for Long Life

Regular maintenance is vital for making certain the durability and optimal efficiency of commercial scales. A methodical approach to maintenance not just extends the life of the devices yet also assures exact dimensions critical for functional effectiveness.

Begin with regular assessments to identify deterioration, ensuring elements such as load cells and screens operate appropriately. Calibration checks ought to be conducted frequently, ideally after significant adjustments in ecological problems or adhering to hefty usage. Exact calibration is essential for compliance with industry requirements and for maintaining the integrity of weight dimensions.

Furthermore, it is a good idea to establish a maintenance routine that videotapes each solution go to, calibration, and any type of repair services executed. This documents help in monitoring tools efficiency and planning for future maintenance requirements.

Finally, training staff on appropriate use and care methods will reduce the possibility of operator mistake, further improving scale integrity. By prioritizing regular upkeep, organizations can ensure that their industrial scales continue to be a trustworthy asset in their operations.

Final Thought

In recap, the integration of trustworthy check my site industrial scales is crucial for enhancing business operations throughout different markets. Exact weighing not just decreases disparities but likewise enhances stock monitoring and ensures conformity with industry criteria. The selection of appropriate devices, paired with contemporary technical improvements, can significantly enhance effectiveness and decrease operational costs. Regular maintenance and training more add to the long life and precision of these ranges, cultivating data-driven decision-making and inevitably supporting overall organization success.

Industrial ranges come in different kinds, each designed to satisfy particular considering requirements throughout different sectors. Crane scales are additionally noteworthy; they are suspended from a structure to evaluate heavy materials in industrial setups.Various markets might require unique types of scales, such as flooring ranges for heavy tons, bench scales for smaller products, or mobile ranges for adaptability - Industrial Scales. Digital scales typically supply enhanced accuracy and convenience of usage, while analog scales might be enough for less demanding applications.In summary, the integration of trusted industrial ranges is necessary for improving business operations across various markets